What is Vacuum Forming?

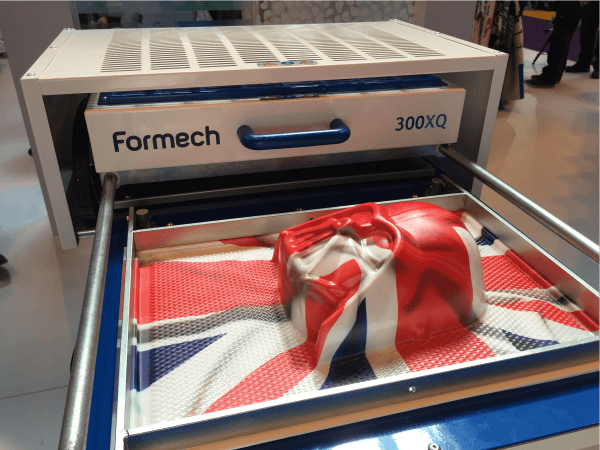

Vacuum forming is a manufacturing process used to shape plastic sheets into various forms and shapes by heating the plastic material until it is soft and pliable, then stretching it over a mold, and using a vacuum to suck the air out between the mold and the plastic sheet. This creates a vacuum pressure, which forces the heated plastic sheet to conform to the mold’s shape, resulting in a three-dimensional plastic product.

The process is widely used to create a range of plastic products, from simple trays and containers to more complex shapes, such as car dashboards, airplane components, and medical devices. It is also used in prototyping, packaging, and other industrial applications where a low-cost, quick-turnaround method of creating plastic parts is required.

Vacuum forming is a popular alternative to other plastic forming methods, such as injection molding or blow molding, as it is generally less expensive and faster. It is also versatile, as it can be used with a variety of thermoplastic materials, including PVC, PET, ABS, polycarbonate, and more.

How dose Vacuum Forming Works?

Vacuum forming works by heating a flat sheet of thermoplastic material, such as PVC, PET, or polycarbonate, until it becomes soft and pliable. The heated plastic sheet is then stretched over a mold, which is typically made of aluminum, wood, or epoxy, and sealed to the mold frame.

A vacuum is then applied to the backside of the mold, using a vacuum pump or other suction device, which removes the air between the mold and the plastic sheet. This creates a pressure difference that causes the softened plastic to conform to the shape of the mold, creating a three-dimensional object.

Once the plastic sheet has cooled and hardened, the vacuum is released, and the formed plastic object can be removed from the mold. The excess plastic around the edges of the mold, known as the “flash,” is trimmed away, leaving a finished product.

Vacuum forming can be used to create a wide range of shapes and sizes, from small parts to large components, depending on the size of the mold and the capabilities of the vacuum forming machine. The process is also relatively fast and cost-effective, making it a popular choice for prototyping and low-volume production runs.

1:lamps:

2.Heat:

3.Vacuum:

4.Cooling:

5.Demolding:

6.Trimming:

These terms seem to be related to the vacuum forming process, so I’ll provide a brief explanation of how they are relevant to the process:

Lamps: In vacuum forming, heating the plastic sheet until it becomes soft and pliable is a critical step. This is typically achieved using infrared lamps or other heating elements, which are positioned above or below the plastic sheet.

Heat: As mentioned above, heat is necessary to soften the plastic sheet and make it pliable enough to be vacuum formed. The exact temperature and duration of heating will depend on the type of plastic being used and the size and complexity of the mold.

Vacuum: Once the plastic sheet is heated and positioned over the mold, a vacuum is applied to the backside of the mold to remove the air between the plastic and the mold. This creates a pressure difference that forces the plastic sheet to conform to the shape of the mold.

Cooling: After the vacuum forming process is complete, the plastic part needs to be cooled and hardened before it can be removed from the mold. This can be achieved using air or water cooling, depending on the type of plastic being used.

Demolding: Once the plastic part has cooled and hardened, it can be removed from the mold. This can be done manually or using an automated demolding system.

Trimming: After the plastic part has been demolded, excess material around the edges of the part, known as the “flash,” needs to be trimmed away. This can be done using various cutting tools, such as a router or a knife, to produce a finished part.

What are the Methods of Vacuum Forming?

There are several methods of vacuum forming, which vary depending on the type of mold and equipment used. Here are some of the most common methods:

Single Station Vacuum Forming: This is the most basic type of vacuum forming, where a single mold is used to create one part at a time. The plastic sheet is heated and positioned over the mold, and a vacuum is applied to the backside of the mold to create the desired shape. Once the part has cooled, it can be removed from the mold and trimmed.

Twin Sheet Vacuum Forming: This method involves using two molds and two sheets of plastic, which are heated and vacuum formed simultaneously to create a hollow part. The two sheets are then joined together, typically using a combination of heat and pressure, to create a sealed part.

Pressure Forming: This is a more advanced type of vacuum forming, where additional pressure is applied to the mold to create a more detailed and precise part. This method is typically used to create parts with deep draws, sharp corners, or intricate details.

Plug Assist Forming: This method involves using a plug, typically made of wood or foam, to help shape the plastic sheet around the mold. The plug is positioned on top of the plastic sheet and pressed down onto the mold, creating a more even distribution of material and reducing the likelihood of thin spots or defects.

Billow Forming: This method involves using a heated air source to create a “billow” or bubble in the plastic sheet, which is then drawn down onto the mold using vacuum pressure. This technique is often used to create parts with complex shapes or deep draws.

Each method of vacuum forming has its own advantages and disadvantages, and the choice of method will depend on the specific requirements of the part being produced.

The Materials Of Vacuum Forming

Vacuum forming can be used with a variety of thermoplastic materials, which become soft and pliable when heated and can be formed into three-dimensional shapes using vacuum pressure. Here are some common materials used in vacuum forming:

Acrylonitrile Butadiene Styrene (ABS): ABS is a strong, impact-resistant plastic that is commonly used in the automotive, consumer goods, and electronics industries. It can be easily colored and has good dimensional stability, making it a popular choice for vacuum forming.

Polycarbonate (PC): PC is a durable, transparent plastic that is commonly used in applications where high impact resistance and optical clarity are required. It can be easily molded and formed, making it a good choice for vacuum forming.

High Impact Polystyrene (HIPS): HIPS is a lightweight, low-cost plastic that is commonly used for packaging, signs, and displays. It can be easily vacuum formed and has good dimensional stability, making it a popular choice for low-volume production runs.

Polyethylene (PE): PE is a lightweight, flexible plastic that is commonly used for packaging and consumer goods. It is easy to vacuum form and has good impact resistance, but can be prone to warping if not properly cooled.

Polypropylene (PP): PP is a tough, lightweight plastic that is commonly used in automotive, packaging, and consumer goods. It can be easily vacuum formed and has good chemical resistance, but can be prone to warping and distortion if not properly cooled.

There are many other types of thermoplastic materials that can be used in vacuum forming, each with its own unique properties and advantages. The choice of material will depend on the specific requirements of the part being produced, such as strength, durability, and visual appearance.

Applications of Vacuum Forming

Vacuum forming is a versatile manufacturing process that can be used in a wide range of industries and applications. Here are some common applications of vacuum forming:

Packaging: Vacuum forming is commonly used to produce packaging materials, such as blister packs, trays, and clamshells. These can be custom-designed to fit specific products and provide protection during shipping and handling.

Automotive: Vacuum forming is used to create interior and exterior automotive components, such as dashboards, instrument panels, and trim pieces. These parts can be produced in low to medium volumes, making vacuum forming a cost-effective alternative to injection molding.

Signage and displays: Vacuum forming can be used to create a variety of signage and display components, such as channel letters, light boxes, and point-of-purchase displays. These can be produced in a range of colors and finishes to meet specific branding requirements.

Consumer goods: Vacuum forming is used to produce a variety of consumer goods, such as toys, games, and household items. These parts can be produced in low to medium volumes, making vacuum forming an economical choice for small-scale production runs.

Medical equipment: Vacuum forming is used to create a variety of medical equipment components, such as trays, housings, and covers. These parts can be produced in a range of materials that meet strict medical industry standards for cleanliness and durability.

Aerospace: Vacuum forming is used to create lightweight, aerodynamic components for the aerospace industry, such as interior panels, instrument housings, and ventilation ducts. These parts can be produced in complex shapes and sizes to meet specific design requirements.

Overall, vacuum forming is a versatile manufacturing process that can be used in a wide range of applications across multiple industries.

Advantages and disadvantages of Vacuum Forming

Vacuum forming is a popular manufacturing process due to its many advantages, such as low tooling costs, quick production times, and design flexibility. However, there are also some disadvantages to consider. Here are some of the key advantages and disadvantages of vacuum forming:

Advantages:

Low tooling costs: Compared to other manufacturing processes like injection molding or CNC machining, vacuum forming requires minimal tooling, making it a cost-effective option for low to medium volume production runs.

Quick production times: Vacuum forming can produce parts quickly and efficiently, with production times ranging from minutes to hours depending on the complexity of the part.

Design flexibility: Vacuum forming can create parts in a wide range of sizes, shapes, and materials, making it a highly flexible process for custom designs.

Minimal material waste: Vacuum forming uses only the amount of material necessary to create the part, minimizing waste and reducing material costs.

Smooth surface finish: Vacuum forming can produce smooth, uniform surface finishes with no visible parting lines or seams.

Disadvantages:

Limited material selection: Vacuum forming is best suited for thermoplastic materials, which limits the range of materials that can be used for manufacturing.

Limited part thickness: Vacuum forming is limited in terms of the thickness of parts that can be produced, typically ranging from 0.010 to 0.500 inches.

Limited precision: Vacuum forming may not be suitable for highly precise parts or parts with tight tolerances due to the stretching and distortion of the plastic sheet during the forming process.

Limited production volume: Vacuum forming is best suited for low to medium volume production runs, making it less suitable for high volume manufacturing.

Tooling limitations: Vacuum forming molds may require regular maintenance and replacement, and are limited in terms of complexity and detail compared to other manufacturing processes like injection molding.

Overall, vacuum forming offers many advantages for producing custom parts quickly and cost-effectively, but it is important to consider its limitations and determine whether it is the best manufacturing process for a particular application.

What is the Difference Between Vacuum Forming and Injection Molding?

Vacuum forming and injection molding are both popular manufacturing processes for creating plastic parts, but there are some key differences between the two methods.

Process: Vacuum forming uses a sheet of plastic that is heated and then drawn over a mold using a vacuum to create the shape of the part. Injection molding, on the other hand, injects molten plastic into a mold under high pressure to form the part.

Tooling: Vacuum forming requires less tooling than injection molding, as only one mold is needed to create the part. Injection molding, on the other hand, requires a mold for both the part and the runner system.

Part size: Vacuum forming is better suited for larger parts with simpler geometries, while injection molding is better suited for smaller parts with complex geometries.

Material selection: Vacuum forming is best suited for thermoplastic materials, while injection molding can use a wider range of materials, including thermosetting plastics and rubber.

Production volume: Vacuum forming is best suited for low to medium volume production runs, while injection molding is better suited for high volume production runs.

Surface finish: Vacuum forming can produce smooth, uniform surface finishes, while injection molding can produce more complex surface finishes with a range of textures and patterns.

Cost: Vacuum forming is generally less expensive than injection molding for low volume production runs, but injection molding becomes more cost-effective as the production volume increases.

Overall, vacuum forming and injection molding have different strengths and weaknesses, and the choice between the two methods depends on factors such as part size, geometry, material selection, production volume, and cost.